-

Careers

Look for jobs and resources in Decatur & Macon County here.

-

Benefits

Find out the benefits of working here (besides a paycheck!).

-

Industries

Up-to-date information on the industries located here.

-

Startup

Ready to start your own business? Get started today.

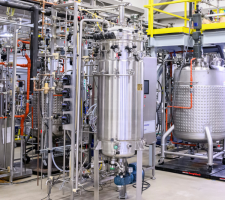

Production Supervisor - 3rd shift

Mueller Co.

This job is no longer accepting applications

See open jobs at Mueller Co..See open jobs similar to "Production Supervisor - 3rd shift" Limitless Decatur.The 3rd shift Production Supervisor effectively plans and implements work for assigned production ensuring that parts and/or materials and manpower are available. The Supervisor implements flow manufacturing techniques where appropriate.

Essential Duties and Responsibilities:

Plan and lead the activities of production processes and personnel on various shifts during the manufacturing/assembly of products.

Partner with the Production Manager, Production Planning, and Materials departments to establish production priorities and plans.

Direct production operations in accordance with established priorities and sequences for manufacturing products using knowledge of production processes and methods, machine and equipment capabilities and skilled labor.

Analyze production schedules to estimate work requirements for completion of job assignments and adjust to meet scheduled requirements.

Assist Quality Assurance and Manufacturing Engineering personnel in testing, troubleshooting, and modifying processes to improve production methods, equipment performance and quality of products.

Advise managers and supervisors of production issues and offer suggestions for changes in working conditions, design, test, production procedures, and the use of equipment.

Meet or exceed goals established for safety, labor efficiencies, schedule attainment, scrap, rework, and any other production related goals.

Initiate, suggest, and implement plans to motivate, empower, and develop workers to achieve work goals in a team environment.

Supervise and assist in the setup, operation, troubleshooting and maintenance of various automated machines, assembly equipment and/or machining centers.

Conduct performance appraisals and make recommendations for promotions, transfers, discharges, and disciplinary measures.

Obtain critically needed products from material as directed, performing any necessary operations / processes to expedite requirements toward production plans.

Implement lean techniques and principles such as 5S, standardized work, waste identification and elimination, value stream mapping, team based multi-skilled workforce, one piece flow technology, visual factory concepts, and total productive maintenance

Required Experience and/or Education:

Bachelor's degree in a relevant field of study or an equivalent combination of education and work-related experience.

1-3 years of experience in manufacturing environment involving high speed machining

Strong leadership, communications, and interpersonal skills with ability to interact with all levels of employees, customers, and outside professionals.

-

Behavior and experience demonstrated with results for:

Understanding of market dynamics and financial implications for strategic decisions.

Leadership style supportive of team and group communication and relationships with peers and customers.

Leadership by example via energy level, diligence, aggressiveness, and overall work ethic.

Ability to work within a high velocity, autonomous and demanding business culture.

Unequivocal commitment to the highest standards of personal and business ethics and conduct.

Perks of Joining Our Team:

Medical, Dental & Vision Insurance

401(k) Retirement Plan with company match

Paid Holidays and Vacation

Tuition Reimbursement Program

Referral Bonuses

Mueller Stock options

Overtime eligible

Short and Long Term Disability

And more...

We are an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, sex, sexual orientation, gender identity, national origin, disability, status as a protected veteran, or any other category protected by law.

This job is no longer accepting applications

See open jobs at Mueller Co..See open jobs similar to "Production Supervisor - 3rd shift" Limitless Decatur.