-

Careers

Look for jobs and resources in Decatur & Macon County here.

-

Benefits

Find out the benefits of working here (besides a paycheck!).

-

Industries

Up-to-date information on the industries located here.

-

Startup

Ready to start your own business? Get started today.

Quality Technician

T/CCI Manufacturing

Quality Technician

TCCI Manufacturing LLC

2120 N 22nd Street

Decatur IL, 62526

$20.00 - $22.00 per hour

TCCI Manufacturing

Quality Technician

Company Background

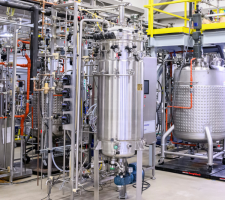

TCCI Manufacturing is a world leader in compressor technology for commercial vehicle, automotive and same-day delivery vehicles. Our global footprint spans 10 locations across the US, China, India, Germany, UK, Ireland, Spain, Argentina, Mexico, and Argentina—employing more than 650 employees worldwide.

TCCI has become one of the leading global Electric Compressor (EC) Manufacturers for the commercial & heavy-duty sectors, as well as automotive specialty vehicle markets. As we look to the future, we will pioneer technology in electrification and support our customers’ plans for a full electrification solution that includes vehicle production, charging, route planning and infrastructure.

Role Responsibilities

TCCI is actively expanding its Quality team in Decatur, IL, to facilitate its growth and capitalize on emerging market prospects. To this end, the company is actively recruiting a Quality Technician who will focus on improving customer satisfaction by improving the Quality of TCCI Products and Services while reducing failures and conformity to specifications.

Key Responsibilities

- All Duties of a Quality Inspector: Effectively performs all core inspection, auditing, and documentation tasks.

- Process Documentation: Develop, write, and revise detailed Standard Operating Procedures (SOPs), work instructions, and inspection plans used by the Quality Inspector role.

- Corrective Action Support: Participate in investigating the root cause of non-conformances and assist in implementing temporary and permanent corrective actions (CAPA).

- Continuous Improvement: Identify bottlenecks and inefficiencies in quality processes (e.g., inspection time, data collection) and propose process improvements to enhance overall efficiency and accuracy.

- Training: Provide basic training and guidance to Quality Inspectors on new inspection techniques or updated procedures.

- NCM Disposition: Review and disposition Non-conforming Material that has been put on hold.

- Data Analysis: Collect and analyze quality data (e.g., defect rates, trending) to identify areas of concern.

Key Qualifications

– Experience in manufacturing or quality setting

– Knowledge of product development processes

– Geometric Tolerance

– Experience with measuring tools such as Calipers, Micrometers, CMM, Scanner, and various gages

– Blue Print Reading

– Ability to effectively communicate with quality engineers and production floor

– Proficiency in Excel

– Ability to learn and use technology systems

– Strong Communication Skills

Preferred Qualifications

- Advanced Technical & Analytical Skills: Proficient in statistical techniques like Statistical Process Control (SPC) and capable of performing basic data analysis.

- Procedure Writing: Excellent written communication skills for creating clear, unambiguous, and technically accurate documentation (SOPs, WIs).

- Problem-Solving Methodologies: Foundational knowledge of root cause analysis tools (e.g., 5 Whys, Fishbone/Ishikawa diagrams).

- Interpersonal Communication: Ability to collaborate with Production, Engineering, and other departments to gather information and implement changes.

- Define Measurement Methods: Basic understanding of inspection tooling requirements and the ability to recommend improvements.

Education

High School Diploma or GED required.